Environment

Innovative solutions to water treatment powered by Graphene

Oil

Absorbent

Boom

Why? Severe environmental and ecological issues resulting from oil spills are being managed largely by the deployment of oil containment boom. The absorbent boom contains synthetic fibers (polypropylene) packed in mesh tubes, which absorbs the oil without absorbing water. Once saturated, the sorbent oil booms must be discarded and can no longer be reused.

Where Graphene Technology Comes In

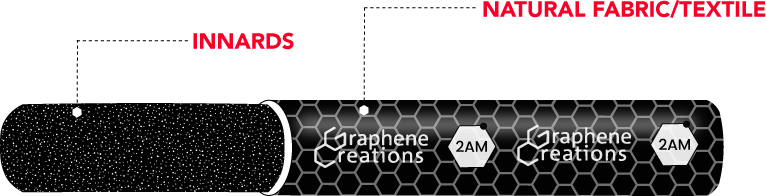

While graphene oil boom works similarly to traditional polypropylene oil boom, it is reusable and compostable. The oil content in the boom can be extracted and has market value. Once emptied out the oil, the boom can be reused many times over. Expanded graphite oil boom is light in weight and is capable of absorbing oil 66 times its weight (ie. 1 gram of graphene can absorb 66 grams of oil). Graphene oil boom is a vessel made of graphene coated biodegradable natural fabric/textile packed with graphene flakes. Due to its lightness and hydrophobic surface, it floats on the surface of water and repels water molecules. As it comes into contact with oil layer, it absorbs oil molecules very quickly by capillary force and oleophilicity.

Oil Absorbent Boom

Our Current Status

Prototype in progress

Estimated time to market: 2022

Modular

Waste water

Treatment System

Why? Traditional industrial wastewater treatment system for highly contaminated wastewater requires tremendous amount of energy and high investment. Common solution under existing facility is to repeat the treatment process until the treated water meets the state/local requirements. Such redundancy results in high cost of energy and long processing hours means limited opportunity to scale.

Modular Waste Water Treatment System

Where Graphene

Technology Comes In

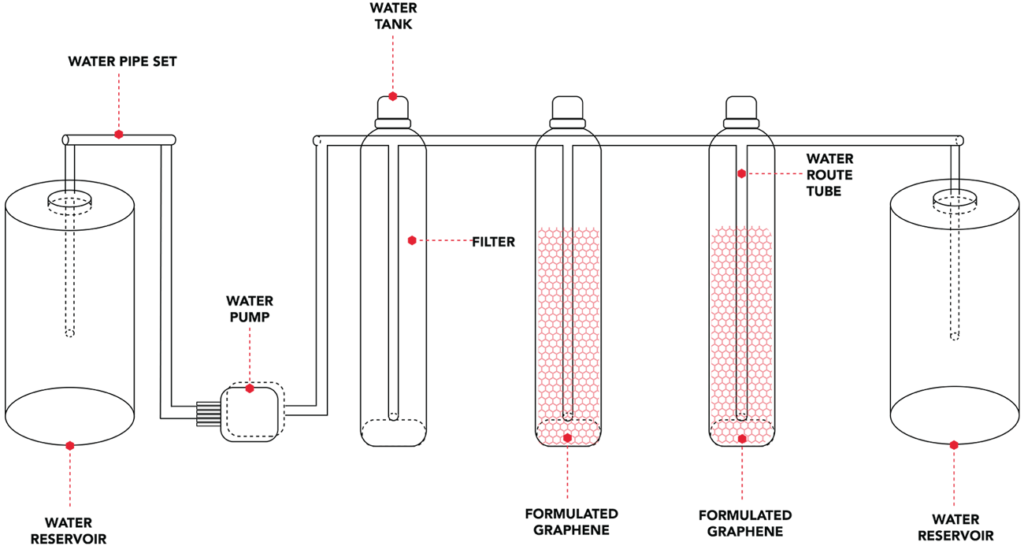

Graphite and formulated graphene are capable of reducing the levels of C.O.D and F.O.G and the use of the correct filtration will ensure suspended solids are also reduced. With modular graphene filtration system, factories can choose to reduce time from start to finish by integrating this step into the existing facility. Industry most suitable for this modular system is textile and paper manufacturer where C.O.D, F.O.G and suspended solids are most prominent.

Modular Waste Water Treatment System

Our Current Status

5/50-51 ซอย ศรีนครินทร์ 46/1

หนองบอน ประเวศ

กรุงเทพฯ ประเทศไทย

บอกเล่า ความต้องการของธุรกิจคุณ

Manufactured by:

Graphene Creations Company, Ltd.

944 Rama 4 Road, Room S25033, Floor 25, Mitrtown Office Tower, Wangmai, Pathumwan, Bangkok 10330